Total Solution for Lee Tunnel LaserFlow Project

Abstract

RS Hydro have finished a flagship project working with MVB JV at Thames Water's Lee Tunnel as part of the Thames Water Tideway Scheme. Ten ATEX-rated MCERTS-certified non-contact LaserFlows have been installed in 5 large tunnels to replace failing wetted area-velocity sensors that needed continual maintenance. Installed in pairs, each pair of LaserFlows act to provide high accuracy flow measurement up to 20m3/sec (equivalent to nearly 30000 tonnes per day) of sewage in peak flow conditions. The LaserFlows provide data in real-time but with improved accuracy and less maintenance over their predecessors. The project is a real turning point for wastewater flow measurement in the UK in that it shows that there are no longer any advantages of using wetted area velocity sensors when compared to using high accuracy non contact flow meters.

Industry

UK Water Industry, Thames Water/ MVB JV

Equipment Used

10 ISCO EX LaserFlows with integral Ultrasonic level sensors, Signature flow meter with 4-20mA output and relay card.

Background

The Lee Tunnel project was designed to prevent storm water entering into the River Lee at Abbey Mills, London by providing a storage system for over 380,000m3 that transports flows to Beckton Waste Water Treatment Works (WWTW). The tunnel system is designed to have a maximum combined inflow of 52m3/sec. Once this flow is met the excess is discharged into the River Thames at Beckton via the overflow shaft and outfall culverts. During storms, the new pumping station at Beckton will drain the Lee Tunnel system and pass the storm water forward for treatment at Beckton WWTW. Much of the sewage from North London via the Northern Outfall Sewer (NOS) is fed into the Lee Tunnel on its way to Beckton WWTW.

Previously each tunnel used an ultrasonic level sensor and three wetted area velocity sensors but due to changes in the H&S Policy and maintenance/performance issues, Thames Water required that these flow meters were replaced by flow meters that could be maintained from the top of the barrel instead of requiring entry into the NOS. Initially the LaserFlow was installed alongside a competitor's radar velocity sensor and existing wetted area velocity meters. The LaserFlow outperformed all of the flow meters convincingly and was therefore selected by Thames Water to be installed in all of the 5 barrels with a duty/hot standby flow meter in each tunnel. All of the installations are also required to be MCERTS compliant; given that the installed uncertainty of a flow meter must be less than 8.0% the LaserFlow is the only flow meter on the market that can realistically achieve this.

Previously each tunnel used an ultrasonic level sensor and three wetted area velocity sensors but due to changes in the H&S Policy and maintenance/performance issues, Thames Water required that these flow meters were replaced by flow meters that could be maintained from the top of the barrel instead of requiring entry into the NOS. Initially the LaserFlow was installed alongside a competitor's radar velocity sensor and existing wetted area velocity meters. The LaserFlow outperformed all of the flow meters convincingly and was therefore selected by Thames Water to be installed in all of the 5 barrels with a duty/hot standby flow meter in each tunnel. All of the installations are also required to be MCERTS compliant; given that the installed uncertainty of a flow meter must be less than 8.0% the LaserFlow is the only flow meter on the market that can realistically achieve this.

RS Hydro were subsequently awarded the contract to design, install, commission and provide O&M manuals for all 10 flow meters. As part of the project RSH were responsible for creating a quality management plan, quality plan, an Inspection & Testing Plan (FAT & SAT), commissioning, a full handover O&M package plus training to MVB & Thames Water personnel.

As part of the installation, the existing failing area velocity sensors had to be removed along with their associated transmitters. Due to the H&S and logistical controls required to remove the wetted area velocity sensors each tunnel had to be isolated in turn. Once removed it was possible to install the Duty/Standby meters within just a few hours. The next pair of flow meters for the next barrel were installed once the previous barrel had been recharged and the lock-offs for the next tunnel were in place. Installation of all 10 flow meters were installed over a two-week period but due to logistical constraints some of the flow meters had to be installed over the weekend.

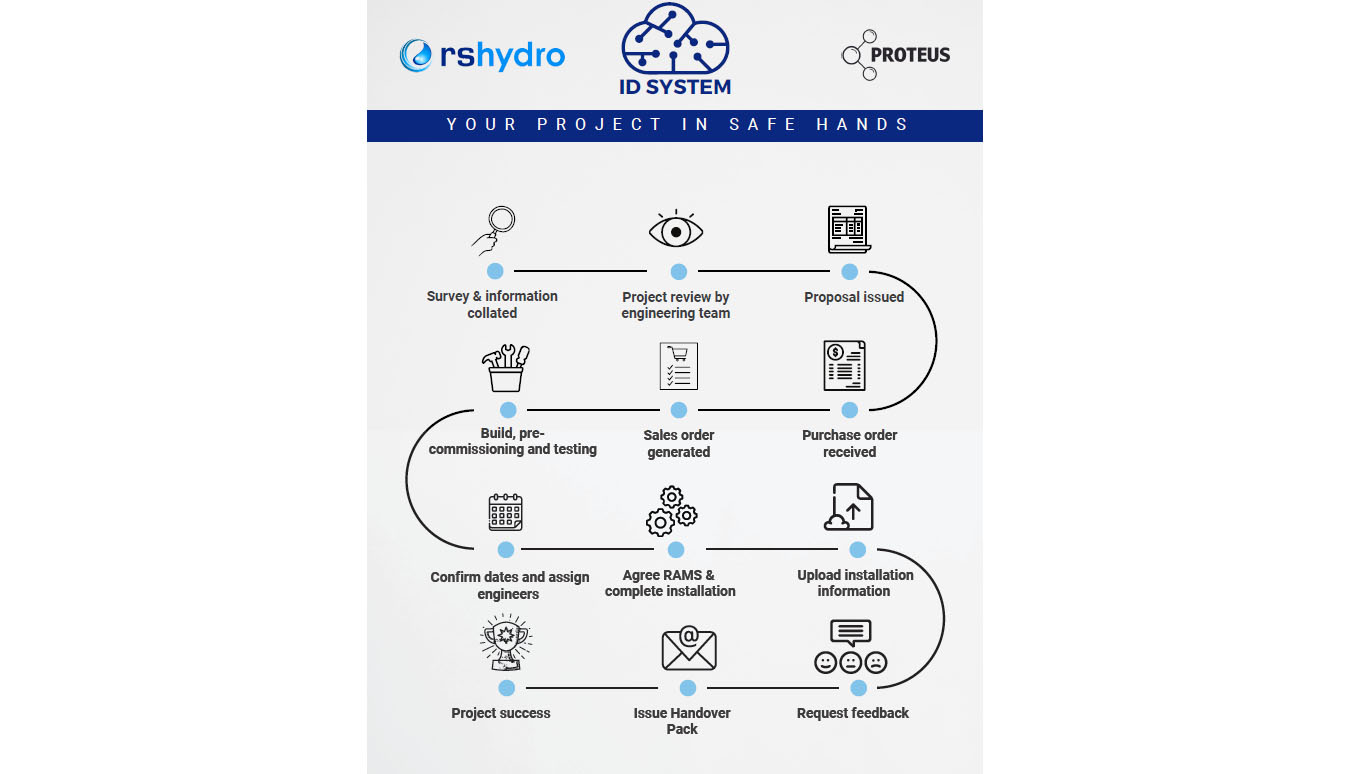

RS Hydro's approach to quality is unprecedented; using our own unique cloud-based ID System which provides a login to our clients as well as our own personnel; our work can be monitored and reviewed at any stage. Every detail about the job from the initial site survey/ quotation and review through to the RAMS, CAD drawings commissioning records and photos, O&M manual and all subsequent site visits or support records are appended to the installation meaning that at any point in the future a summary document (O&M manual and/or equipment/ maintenance log) can be created at a press of a button.

Why the LaserFlow?

The LaserFlow is unique in that it is not only the only non contact flow meter which can penetrate the water's surface but it also has Class 2 MCERTS product certification, making it the most accurate non-contact flow meter available for both ATEX and non-ATEX applications. Its key advantages over other area velocity flow meters include:

- Non-contact for velocity and level

- Single- or multi-point measurement (horizontally and vertically)

- Robust, submersible sensors that are IP68.

- Zero deadband for the measuring level and can measure flows <2mm in depth!

- Bi-directional flow measurement for velocities >0.07m/sec.

- Clean water and Wastewater applications

- Portable & permanent versions, all with quick installation.

- MCERTS Class 2.

- Almost maintenance-free.

Remote Control

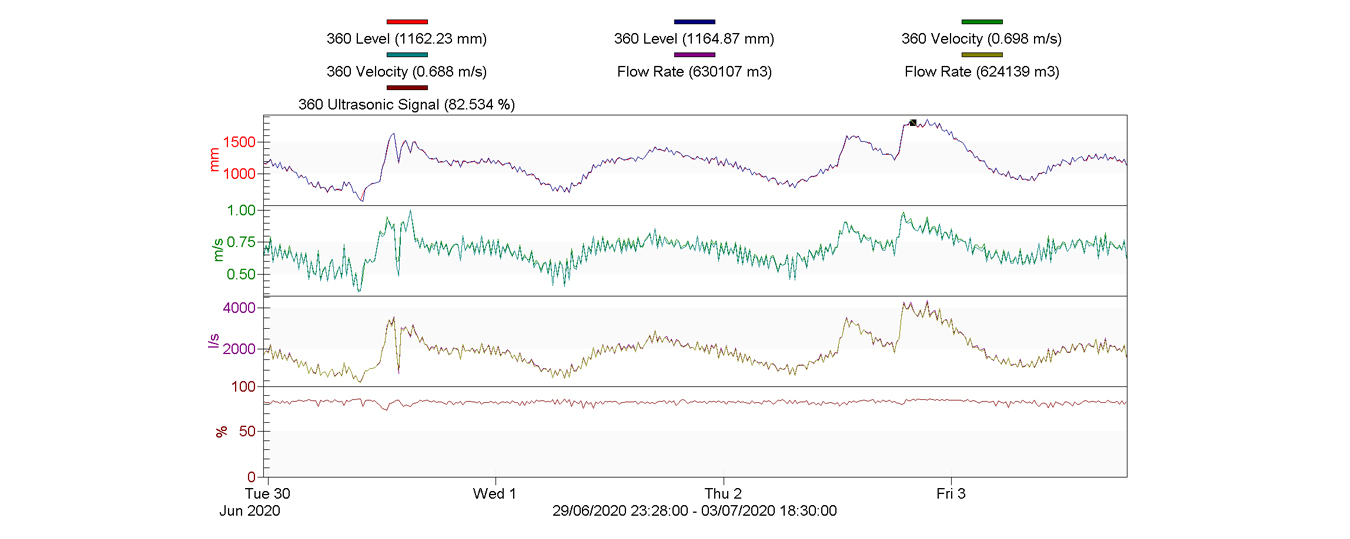

All 10 LaserFlows are fitted with TieNET modems which push the data to RS Hydro's servers every hour. The 'Always On Communication' is two way allowing RS Hydro to provide support at every level 24/7/365. If any of the instruments as much as miss a heart beat then the Signature unit runs a diagnostic capture which is automatically transferred to the server for analysis. The graph below shows both flow meters in a single tunnel. There is typically less than 1% difference between the two flow meters at any time.

Control Room

With the incumbent transmitters removed all 10 transmitters were installed within a single kiosk. Their installation and commissioning was carried out between RSH and MVB engineers. Dan Maunder can be seen here commissioning one of the 10 Signature LaserFlow systems.

Maintenance

The great news is that there is very little to do. Non-contact means that the sensor should almost never touch the water and when you're measuring wastewater that is a massive advantage. With the previous wetted AV sensors, all 5 tunnels had to be drained every month and only when it was safe to do so. Now, all that is required is the odd firmware update and a quick annual level check. Little wonder why the LaserFlow is now regarded as the future of wastewater flow measurement in open channels.